CENTRE FOR ASBESTOS INERTISATION

Friulana Costruzioni Group, has developed a branch of specialised research by investing in research and development and thanks to the experience of the researchers of the internal chemical laboratory of analyses. This branch of specialised research has set up the Rinnova project.

Rinnova is a pilot plant for treating asbestos-containing materials, the first and the only one of its kind on the whole national territory. A new registered patent the project of which has been approved by the Friuli-Venezia Giulia region.

This plant allows an almost total recovery of treatment by-products and aims to inertise asbestos cement, the main material among asbestos-containing materials.

The testing activity in 2022 ended with a positive result and further studies are now in progress in order to use this plant at an industrial level.

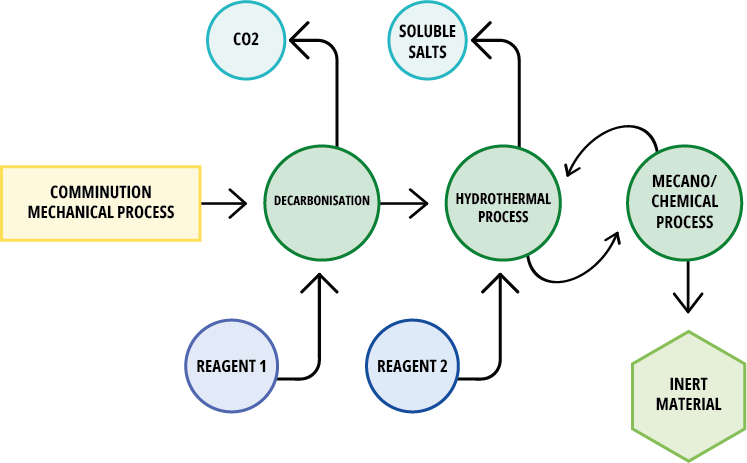

The process

MECHANICAL PROCESS/COMMINUTION

- Waste collection: asbestos cement is collected and carried to the inertisation centre

- Process start in a preset area

- Volumetric reduction

- Comminution

CHEMICAL TREATMENT

The chemical treatment consists of two main phases: decarbonisation and detoxification. These two phases have to operate with different potentialities even though they interact.

The plant can be used according to two steps:

- weight reduction weight reduction;

- complete inertisation..

This entails a modularity of the system/plant that can therefore be used according to clients’ needs up to the step needed.

USE OF INERT MATERIAL AND RECOVERABLE RAW MATERIALS

- Construction materials

- Ceramic ware

- Materials for the photovoltaic or IT industry

- Food- grade CO2